Gas Burners for Ladle Preheating: Consistent Heat for Reliable Metal Pouring

- Sean Davies

- Jul 18, 2025

- 5 min read

Updated: Sep 30, 2025

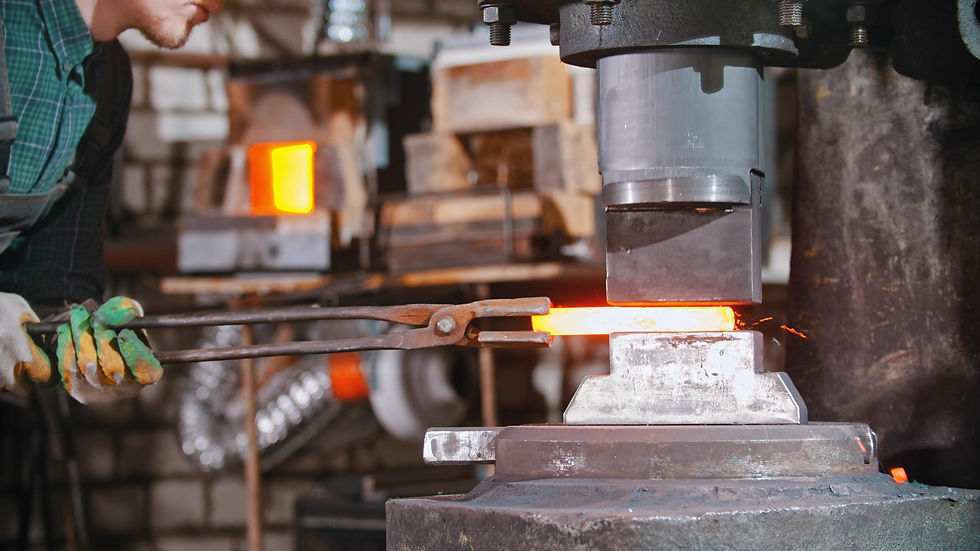

Ladle preheating is a crucial step in metal casting. It ensures the molten metal maintains the right temperature during transportation from the melting area to the pouring moulds. A proper preheating process is vital for producing high-quality metal products. In this blog post, we will discuss how gas burner systems can enhance ladle preheating, the importance of consistent heat, and how Rapidflame's advanced combustion systems can significantly benefit the metals and foundry industries.

Understanding Ladle Preheating

Ladle preheating is about warming the ladle before it carries molten metal for pouring. This practice serves three main functions:

Preventing Thermal Shock: A cold ladle can cause the molten metal to solidify unevenly, which can lead to flaws in the final product.

Minimising Heat Loss: Proper heating keeps the temperature of the molten metal consistent, which is essential for quality.

Maintaining Molten Metal Temperature: A ladle that’s too cool can drop the metal's temperature significantly during transport, risking defects like porosity or inconsistent material properties.

The Role of Gas Burner Systems in Ladle Preheating

Gas burner systems are an effective choice for ladle preheating in numerous foundries. These systems can utilise either air-gas or oxy-gas technologies, providing controlled heat output that ensures even temperature distribution across the ladle.

For example, a well-designed gas burner system may achieve a high heat output precision. This level of control is essential in preventing temperature changes that could affect product quality. Additionally, gas burners are designed for fuel efficiency with low emissions, making them not just effective but also environmentally friendly. They can be activated as needed, ensuring that operational schedules align perfectly with foundry demands.

Importance of Uniform, Reliable Heat

Uniform and reliable heat during ladle preheating is essential for quality metal pours. A loss in temperature can lead to issues such as incomplete solidification and impurities in the molten metal. For instance, in steel production, even a slight variation can decrease the strength of the finished product.

Stable temperatures bolster the metallurgical properties of the cast product, enhancing its strength and durability. By utilising gas burners engineered for ladle preheating, foundries can reduce temperature-related risks, improving the overall reliability of the pouring process.

Benefits of Rapidflame’s Combustion Systems

Rapidflame offers exceptional combustion systems specifically designed for ladle preheating. Here are some of their standout features and benefits:

Reliability: Rapidflame’s systems are built to last, providing consistent performance even in the demanding environment of metal foundries.

Efficiency: With optimised heat output, Rapidflame systems can achieve the required ladle temperature.

Safety: Safety is crucial. Rapidflame's systems incorporate features like flame monitoring and automatic shut-off systems, ensuring safe operations in hazardous environments.

Automation Compatibility: These systems easily integrate with existing automation tools, boosting control and efficiency across the foundry process.

Industries Benefiting from Ladle Preheating

Ladle preheating with gas burner systems delivers considerable benefits across various sectors, including:

Steelworks: Consistent pouring temperatures are crucial for high-quality steel production. Effective ladle preheating can improve production efficiency.

Aluminium Foundries: Aluminium is sensitive to temperature changes. Robust ladle preheating can yield casting results with fewer defects due to thermal stresses.

Non-Ferrous Metals: Other non-ferrous metals experience similar gains from advanced ladle preheating systems, which ensure quality and performance in their final products.

Exploring Oxy-Gas and Air-Gas Systems

Two main types of gas burner systems are used for ladle preheating: oxy-gas systems and air-gas systems.

Oxy-Gas Systems: These systems use a combination of oxygen and gaseous fuel. They produce a hotter flame, making them ideal for high-temperature applications, enhancing heat transfer efficiency and rapid heating. A typical oxy-gas system can achieve temperatures of more than 2,500°C.

Air-Gas Systems: Using air for combustion with gaseous fuel, these systems are often more cost-effective. While they may not reach the extreme temperatures of oxy-gas setups, they provide reliable performance for many ladle preheating needs.

The right choice depends on operational requirements, budget constraints, and efficiency goals. Rapidflame’s engineers can assist in selecting the optimal solution for your specific ladle preheating applications.

Connect with Rapidflame for Customised Solutions

If you are looking to enhance your ladle preheating processes or need assistance in system design, connect with our engineering team. Our experts are prepared to help you optimise your metal casting operations with tailored combustion solutions that fit your unique needs.

Final Thoughts on Ladle Preheating

Gas burner systems for ladle preheating are critical for ensuring consistent quality in metal pouring. The reliability, efficiency, and safety of Rapidflame systems provide a substantial advantage in the competitive metals and foundry industries. Adopting these technologies will not only elevate the quality of your final products but also enhance operational efficiency and reduce costs.

Frequently Asked Questions (FAQs)

1. How does ladle preheating affect the quality of metal casting?

Ladle preheating keeps molten metal at the right temperature, helping to prevent defects like porosity and improving the mechanical properties of the final product.

2. What safety features are included in Rapidflame's combustion systems?

Rapidflame’s systems include features such as flame monitoring and automatic shut-off systems that ensure safe operation.

3. Can ladle preheating systems be automated?

Yes, Rapidflame’s combustion systems integrate smoothly with existing automation tools for improved efficiency and better control.

4. What factors should be considered when choosing between oxy-gas and air-gas systems?

Key factors include the temperature requirements, cost considerations, and specific operational needs of your foundry or processing facility.

The Importance of Ladle Preheating in Metal Casting

Ladle preheating is not just a technical requirement; it is a fundamental aspect of the metal casting process. The temperature of the ladle directly influences the quality of the cast product. Without proper preheating, the risk of defects increases significantly.

The Science Behind Temperature Control

Temperature control is a science that involves understanding the thermal properties of metals. When molten metal is poured into a ladle, it must remain at a specific temperature to ensure proper flow and solidification. If the ladle is too cold, the metal can cool too quickly, leading to poor casting quality.

Enhancing Efficiency with Advanced Technology

Modern technology has made it possible to enhance ladle preheating efficiency. Advanced gas burner systems are designed to provide precise temperature control. This not only improves product quality but also reduces energy consumption.

Conclusion

In conclusion, ladle preheating is a critical process in metal casting. The use of gas burner systems, particularly those offered by Rapidflame, can significantly enhance this process. By ensuring consistent and reliable heat, foundries can improve the quality of their products while also increasing operational efficiency.

Investing in advanced ladle preheating technology is a step towards achieving higher standards in metal casting. It is essential for any foundry aiming to remain competitive in today’s market.